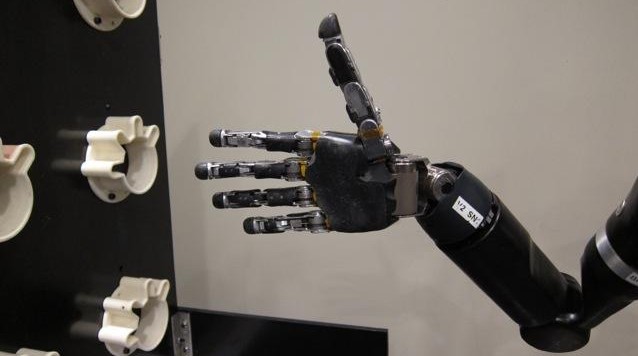

Inspired by lithium batteries and kitchen plastic wrap, engineers at Stanford University have developed a plastic material that helps the body radiate heat, lowering skin temperature and cooling the wearer. To be suitable for clothing, the material is flexible and—importantly—opaque. The teams are now working on a woven version of the textile. Po-Chun Hsu contributed to the research as a member of the Yi Cui research group. We asked him to tell us more.

ResearchGate: Where did the idea for this material come from?

Po-Chun Hsu: The idea of having an infrared transparent cloth to help human body cooling was pretty clear. We knew what this textile should be made of and what the ideal microstructure is, but the challenge was how to make it. Then it occurred to us that the lithium ion battery separator we use every day for battery research may be a great fit. We had a huge roll of it in the Yi Cui research group. It is made of polyethylene, which does not absorb infrared radiation, and it has interconnected nanopores to scatter visible light and provide breathability. We decided to test its photonic and thermal properties and performed numerical simulations in collaboration with Shanhui Fan’s research group. It turns out it works great for cooling. We also benefited from pioneering theoretical work in this field by Gang Chen of MIT. This idea is really a product of cross-disciplinary brainstorming and collaboration.

[tweetthis]High-tech clothing of the future may keep you cool.[/tweetthis]

RG: How does it work?

Hsu: Radiation is a major part of our heat dissipation, especially when we are indoors and at rest. By letting a human body’s infrared radiation escape, this textile provides much greater cooling with the same thickness as normal cloth. In the summer, that means we can reduce the use of air-conditioning and save energy. However, there are very few materials that are infrared transparent. Polyethylene is one of them, but it is also transparent to human eyes and impermeable for air and sweat vapor. Just imagine how uncomfortable it would be to wear kitchen wrap for clothing. So, we propose the idea of creating interconnected nanopores that are a thousandth of the diameter of human hair inside polyethylene: nanoPE. These nanopores not only scatter visible light to give the fabric a white and opaque appearance but also provide pathways for air and vapor transport. This microstructure of nanoPE sounds complex, but it can actually be found in our daily life. The separators inside lithium-ion batteries, which are used to conduct lithium ions and absorb electrolytes, have exactly the right pore size and chemical composition. We measured infrared and visible light properties, as well as thermal insulation properties, and experimentally demonstrated the cooling effect. With further surface modification and processing, this nanoPE radiative cooling textile has breathability and mechanical strength similar to cotton fabric but is 2 degrees Celsius cooler.

RG: What does the material feel like?

Hsu: The textile is nonwoven, so it still feels quite different from the cloth we wear in our everyday life. We are currently working on making a woven nanoPE textile, which we believe will be much softer, more elastic, and feel more like ordinary cloth.

RG: What impact could widespread use of this material have on the environment?

Hsu: At the same heating rate, the simulated temperature of skin covered by nanoPE textile is 2 degrees Celsius cooler than that covered with cotton. If we take advantage of this cooling effect and use it to reduce air-conditioning usage, this would result in, on average, 20 percent energy savings.

The chemicals we used for surface modification are benign to the human body and should not be an issue for the environment. NanoPE itself is in principle just like other polyethylene products, which can be recycled. However, since this is a new textile material, evaluating the full environmental impact will require more comprehensive studies.

RG: Could one wear it in cold temperatures too?

Hsu: Currently our nanoPE textile is for cooling, so it will only make you feel colder.

RG: Do you personally hope to wear clothing made out of this material in the future?

Hsu: Of course! Although there will be a long way to go from lab prototype to commercial product, the idea of surpassing traditional ways of cooling is really appealing to me. Our group is working on making a large-scale woven nanoPE textile, which will provide better wearability for this material, and I am really looking forward to wearing it.

A version of this article entitled “New Clothes to Cool the Skin, No Air-Conditioning Needed” was originally published by ResearchGate.

GotScience.org translates complex research findings into accessible insights on science, nature, and technology. For more science news sign up for our eNewsletter.